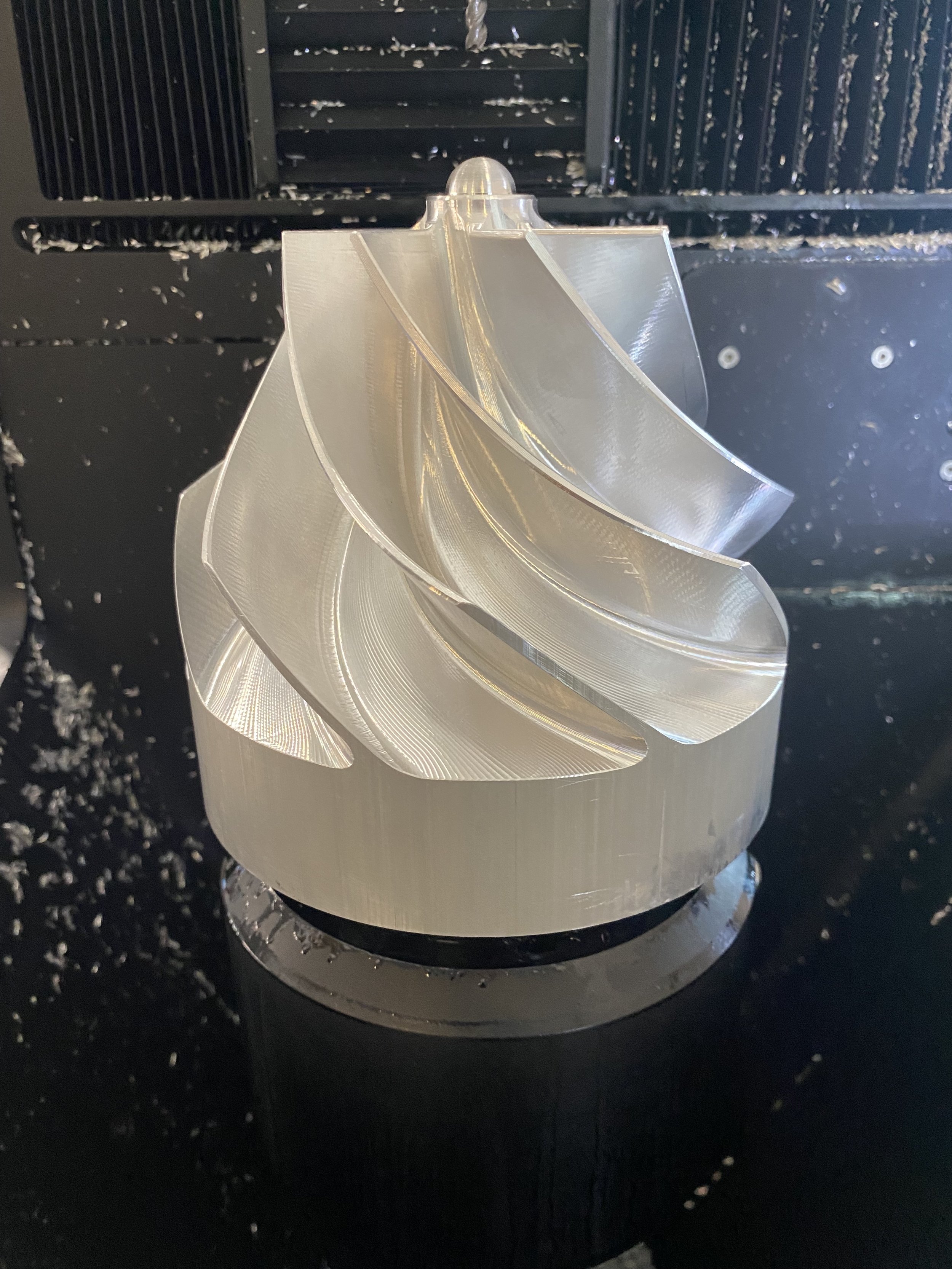

Solo Test: Aluminum Impeller

Test Goals:

maximize single piece work volume of the Solo

test material removal rate in aluminum

first test of the new bellows design

CAM: Mastercam

Material: 6061 Aluminum

Stock size: 6” diameter x 6.1” tall, 17 pounds

Workholding: Schunk vero-s mini90 direct clamping

Tooling:

(Tool 1 ) 3 flute, 3/4” LOC, Destiny Tool 1/4” Flat end mill 1.55” Stick out

(Tool 2) 3 flute ball end mill 1.55” stick out

Roughing feeds/speeds: Top Roughing - (.2” DOC, .15” step over, 50IPM, T1), Blade roughing - (.15” DOC, .15” step over, 66 IPM T1)

Key takeaways:

We removed 90 cubic inches of material in approximately 2 hours with an average material removal rate of 0.75cubic inches/minute and a sustained removal of about 1 cubic inch/minute for the first hour.

The full project filled the 7 gallon chip bin about 75%.

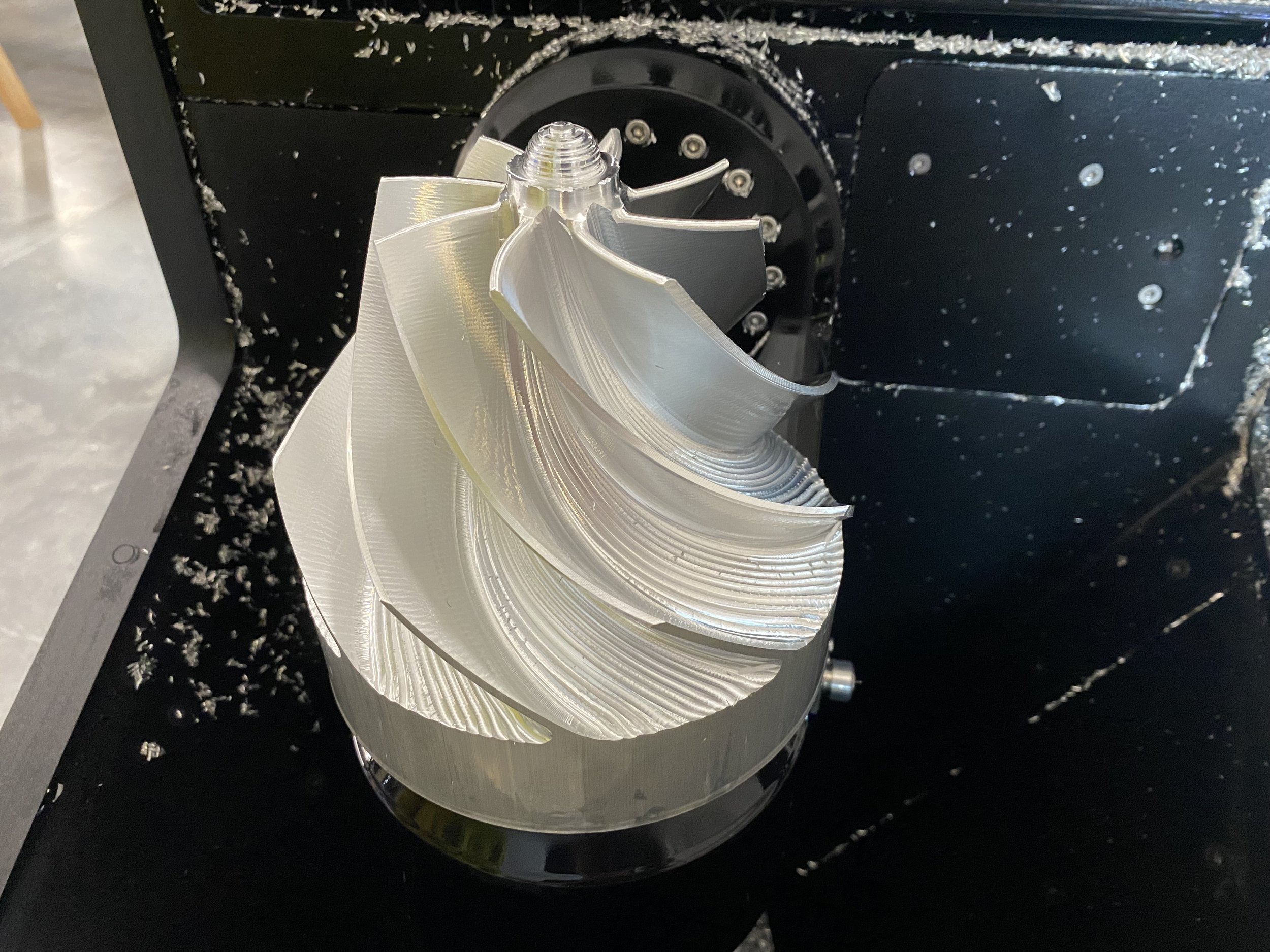

Aluminum impeller roughing

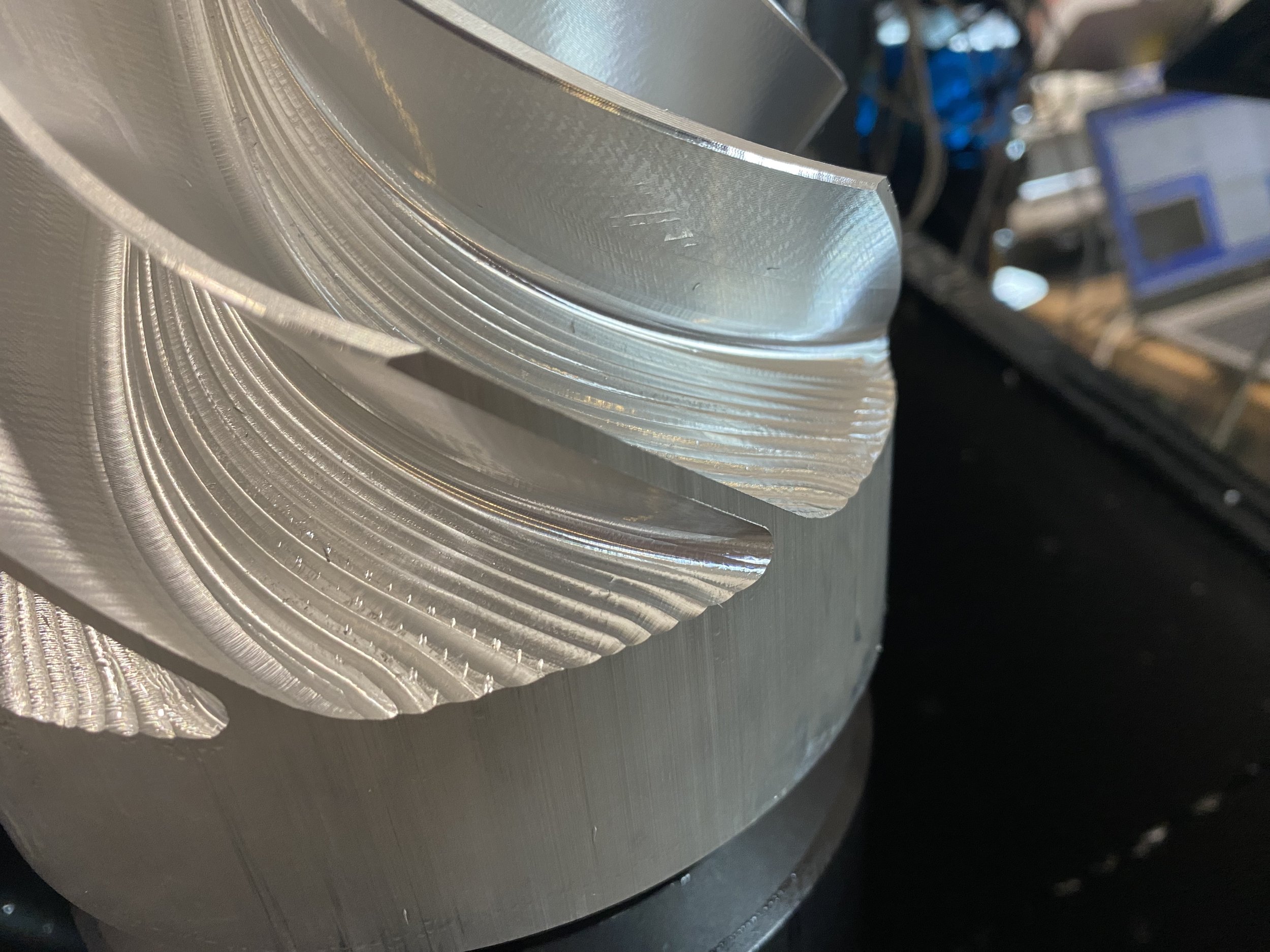

Aluminum impeller finishing.