Solo Material Testing: STEEL

In order to better understand how the Solo would perform when cutting materials with varying degrees of machinability, the Penta team put together a standard test procedure that provides values for key metrics and allows for direct comparison between materials.

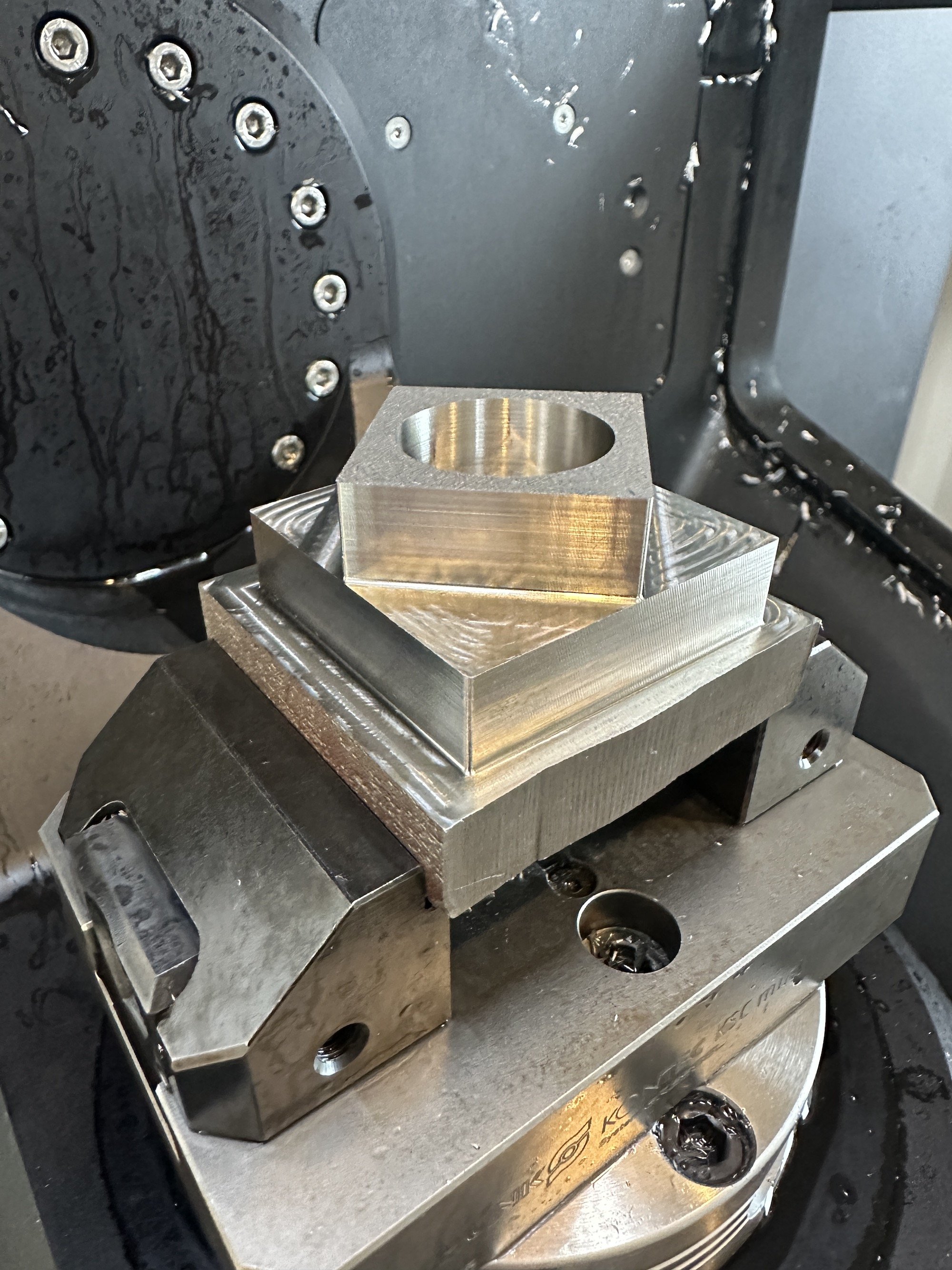

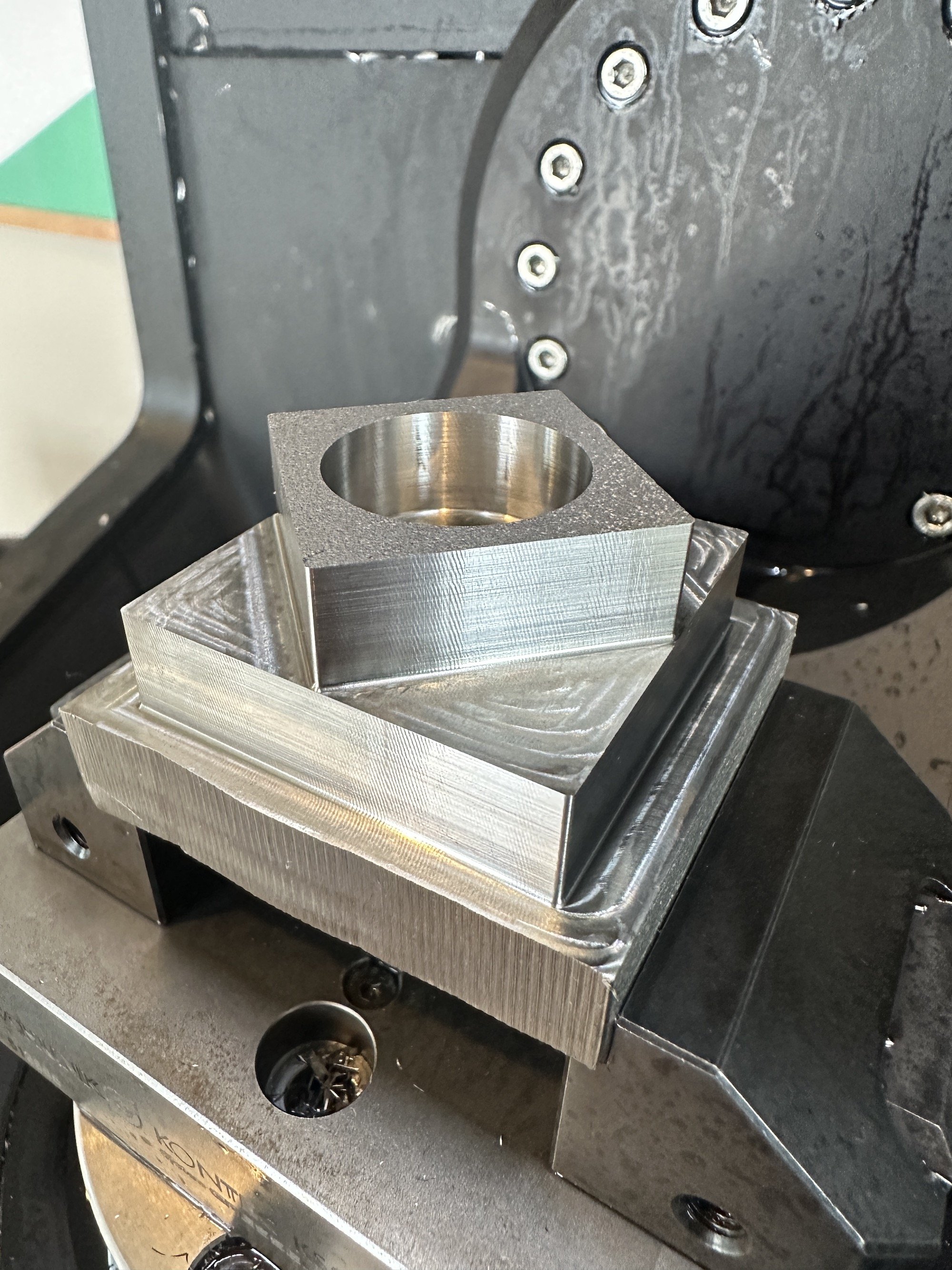

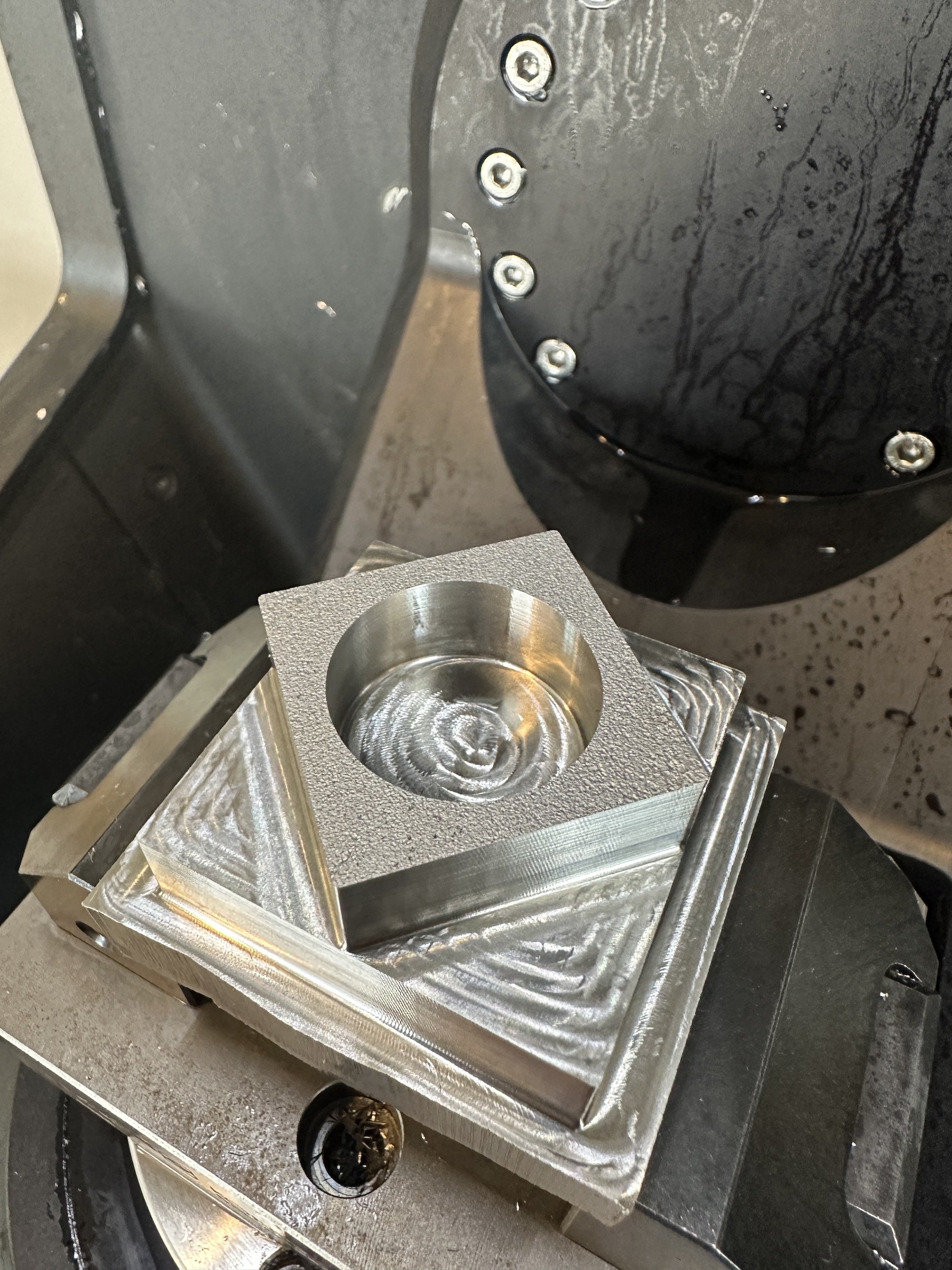

The part chosen for the material testing is a basic part, simply known as the Circle Diamond Square (CDS). The CDS is known to be used by some of the largest manufacturers in the world to test the squareness and accuracy of milling machines, so it seemed a great fit for this test. Each feature - circle, diamond and square - tests the linear axes’ coordination, rigidity and accuracy in a different way, providing insight into the construction and abilities of the machine.

Below are the results for 303 Stainless Steel.

Material:

304/304L stainless steel (McMaster-Carr)

Stock size:

2” x 2” x 1.25”

Workholding:

Schunk vero-s mini90 to Schunk Mini Vise

Tooling:

Destiny Tool DVH41612RC (1/4”, 3 flute)

Stick-out: 28mm

Roughing feeds/speeds:

3819 RPM

12.2 in/min

.0625” WOC

.125” DOC

Finishing feeds/speeds:

3819 RPM

12.2 in/min

.005” WOC

.394” DOC

Results

What went well:

Cut sounded great, tool performed well and the surface finish left behind was really nice.

Note: The finish shown in the pictures above is what was left after 5 finish/spring passes, it is still nice (looks even better in person), however it is not as nice as the finish left after the first finish pass.

Times:

Roughing w/ 1 finish pass: ~34 min 53 sec

Second finish pass: 1 min 40 sec

Total: 36 min 33sec (Max velocity turned down to 12%)

Confirmed Specs:

Max MRR (for this program): ~.1 cubic inches per minute