Pocket NC 101: 5-Axis CNC Machining in the Classroom

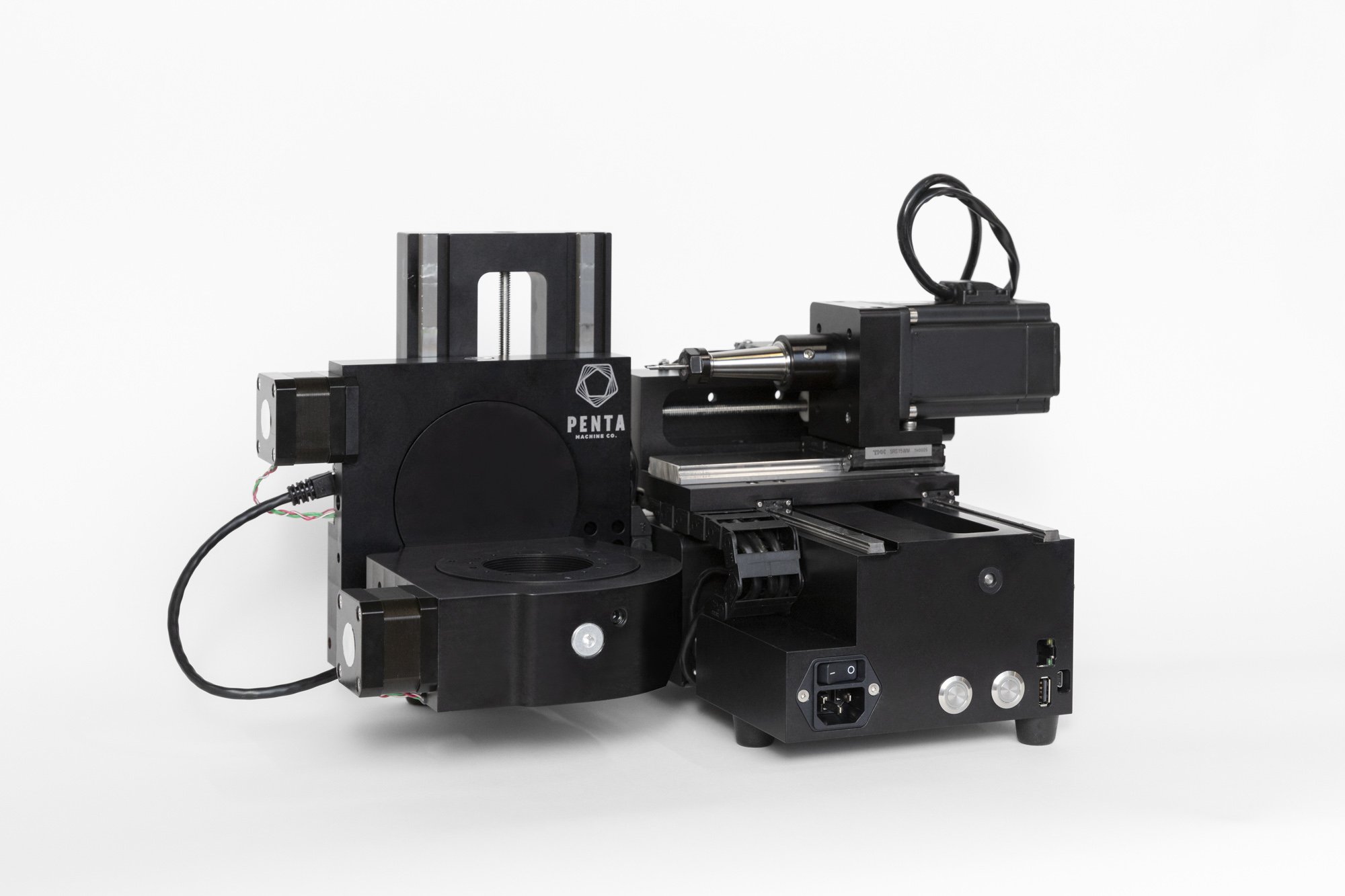

At Penta, our goal has always been to make machining more accessible. Smaller machines and user-friendly designs — all with the benefits of 5-axis capabilities. That was the spark that drove the creation of our flagship machine back in 2015 — the revolutionary Pocket NC.

These new machines and corresponding skillsets required new knowledge, so we started traveling to schools, businesses, and other learning environments, sharing in-person educational introductions to machining on the Pocket NC. But as interest grew, we couldn’t keep up with the demand — so, we created Pocket NC 101. This online course was developed after years of getting to know the questions, learning styles, common pitfalls, and motivating factors that first-time users typically experience.

This article outlines the basics of the course, who it’s for, and what to expect from it, covering frequently asked questions to help you decide if Pocket NC 101 is right for you or your classroom.

Who is Pocket NC 101 for?

This online course is designed to help first-time users get started machining — quickly, easily, and safely. We integrated everything we learned from those in-person teaching moments into one comprehensive curriculum.

Pocket NC 101 is for everyone — no previous experience is required. It’s clear, thorough, and easy to understand, combining videos, workbooks, and hands-on applications. Anyone can gain the essential knowledge and skills to machine multiple parts on the 5-axis Pocket NC in just hours.

How does Pocket NC 101 fit into my curriculum?

With the uptick of interest in machining in schools, we knew that educators needed a quick-start guide that would make it seamless for students to get started. In fact, Pocket NC 101 was created to be so comprehensive and approachable that a teacher doesn’t even have to know machining themselves to be able to hand the course, materials, and machine itself to a group of students and give them the green light for self-guided learning. The CAM portion of the course is currently based around Autodesk Fusion 360.

The course and workbook will walk students through using the Pocket NC machine, with between 8-10+ hours on average of learning time and skill application. Depending on your classroom time, this can be implemented over several days or weeks.

After completing the course, students can take the skills they learned and repeat the process, coming up with their own increasingly complex and creative parts as they start to explore the possibilities and parameters of the 5-axis Pocket NC.

Pocket NC 101 doesn’t provide a full machining education — it typically takes multiple years for individuals to learn everything they need to know to go into machining as a career. Instead, our goal is to create a foundation for students to build from, whether they choose to pursue work as a machinist, or simply use what they’ve learned to explore other possibilities in engineering, coding, design, or hands-on technical roles.

What does Pocket NC 101 cover?

Pocket NC 101 is the complete beginner’s guide to learning, understanding, and utilizing the Pocket NC, one of the world’s most user-friendly 5-axis CNC machines. It goes through safety measures and best practices, as well as the terminology, practical applications, and self-directed usage of the machine. By the end of the course, students will have machined three different parts, learned the user interface, and gotten a taste of programming workflow. They will then be able to get started with their own basic designs and personal projects.

The course curriculum walks students through the following:

The key components and anatomy of the Pocket NC

Understanding the five axes, their names and descriptions, and how the machine manipulates those axes

Startup and shutdown

Using the controls

Setting up cutting tools

The user interface — our proprietary Kinetic Control Software

Jogging (manually manipulating the machine)

Loading the G-code, or program

Using our Simulator program to check code for errors or potential collisions before inputting it into the machine

Introduction to Fusion 360, the powerful cloud CAD, CAM, CAE, and PCB software platform

Cutting a spiral part

Cutting a numbered block

Cutting a rook chesspiece

What do I need to get started?

Getting started with Pocket NC 101 and learning (or teaching) 5-axis machining is simple, with just a few key steps.

Purchase the Pocket NC machine, which includes the vise, extended tool holder with ⅛” ER11 collet, Datron single flute end mill(0068630E), and wax cube — all used in the course

Purchase the Pocket NC 101 course

Provide access to the machine, course, workbook, stock material and ER40 Fixture with 1 inch collet. The full list of items needed to complete the course can be found on our course listing.

After course completion, the skills learned can continue to be applied as students come up with their own projects.

How much does the course cost?

The Pocket NC 101 course, including the workbook and materials, can be accessed for one month with a $70 payment, six months with a $275 payment, or purchased in perpetuity for $375. We also have a free preview of the course available so that you can test it out before committing. You can find the course here.

I have questions about the course or machine. How can I learn more?

The Penta team is here to help. We believe introducing CNC machining to learners of all ages can introduce opportunities for successful, rewarding careers — and, most importantly, introduce new ways of seeing the world.

We’d love to connect with you about adding 5-axis machining to your classroom curriculum. Please reach out to us with any questions at info@pentamachine.com — we look forward to hearing from you!